Secabo Heat Presses - professional solutions for textile finishing and advertising technology

Secabo Heat Presses stand for reliable, precise and efficient finishing processes in textile printing, advertising technology and production. The devices cover all applications: Flex and flock transfer, sublimation, toner transfer, DTF, DTG pre-treatment as well as extensive special applications.

Thanks to their robust design, even temperature distribution and stable pressing force, Secabo Heat Presses enable consistent and reproducible results.

The range is aimed at beginners as well as commercial users and industrial production environments and therefore covers a variety of requirements in professional textile finishing.

Filter products

Hot news from the blog

How do I use compressed air?

Heating element for Secabo TM2 for 2 cups, 7.5 - 9.0cm Grade A

Available, delivery time: 1-3 days

Heating element for Secabo TM2 for conical shot glasses, 3.5/5cm - 4.5/6cm

Available, delivery time: 1-3 days

Heating element for Secabo TM2 for espresso cups, 4.5cm - 5.5cm

Available in 30 days, delivery time 1-3 days

Heating element for TM2 for large conical cups (A-grade)

Available, delivery time: 1-3 days

Secabo TS7 LITE modular Swing Press 40cm x 50cm

Available, delivery time: 1-3 days

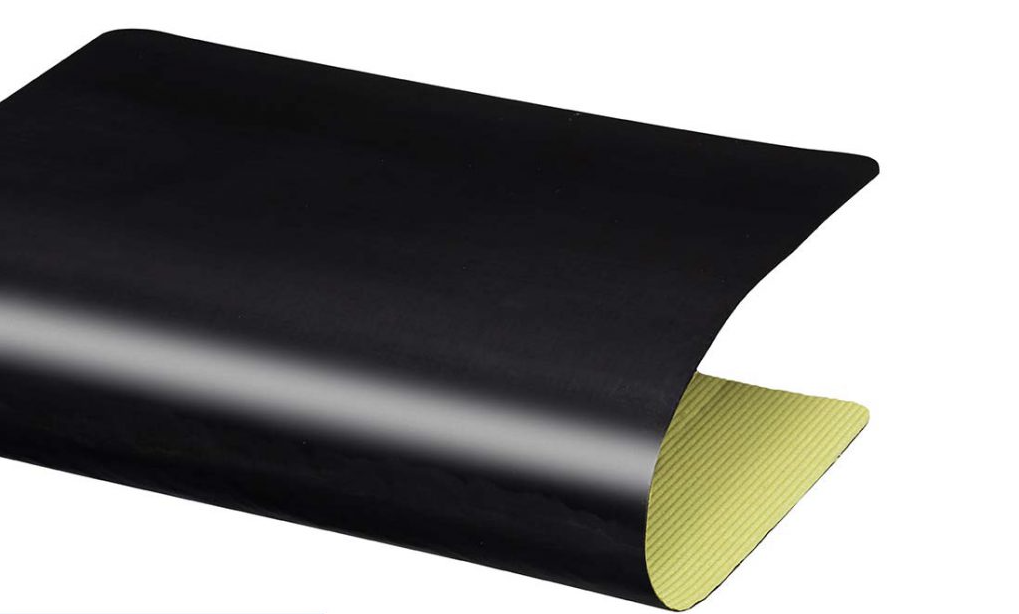

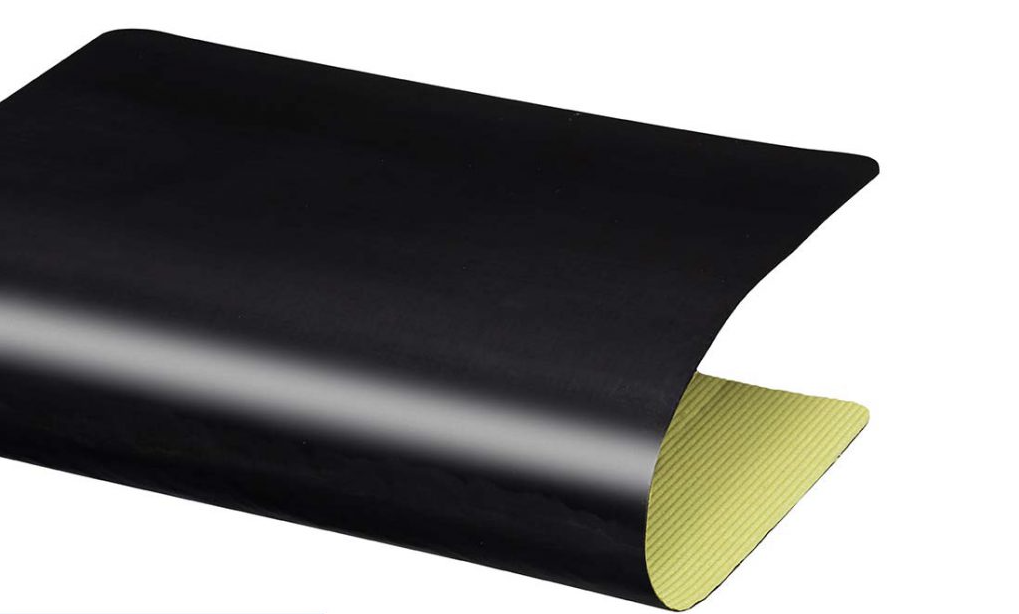

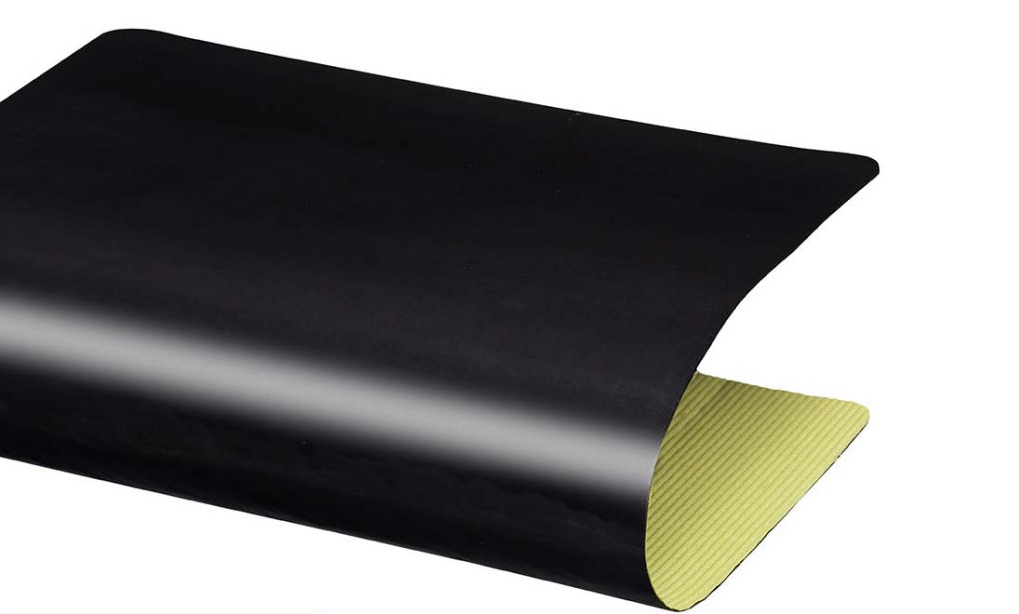

Antistatic heating plate protection, self-adhesive, with PTFE coating 28 x 38 cm

Available, delivery time: 1-3 days

Antistatic heating plate protection, self-adhesive, with PTFE coating 38 x 38 cm

Available, delivery time: 1-3 days

Antistatic heating plate protection, self-adhesive, with PTFE coating 40 x 50cm

Available, delivery time: 1-3 days

Antistatic protective film for PTFE transfers, 38cm x 50cm

Available, delivery time: 1-3 days

Antistatic protective film for PTFE transfers, 50cm x 60cm

Available, delivery time: 1-3 days

Antistatic protective film for PTFE transfers, 80cm x 100cm

Available in 15 days, delivery time 1-3 days

Antistatic protective film for PTFE transfers, 100cm x 120cm

Available, delivery time: 1-3 days

Secabo Heat Presses - professional solutions for textile finishing and advertising technology

Secabo Heat Presses stand for reliable, precise and efficient finishing processes in textile printing, advertising technology and production. The devices cover all applications: Flex and flock transfer, sublimation, toner transfer, DTF, DTG pre-treatment as well as extensive special applications.

Thanks to their robust design, even temperature distribution and stable pressing force, Secabo Heat Presses enable consistent and reproducible results.

The range is aimed at beginners as well as commercial users and industrial production environments and therefore covers a variety of requirements in professional textile finishing.

Finding the right Heat Press: What is important for heat transfers

The success of your textile finishing depends largely on the quality of the Heat Press used. Precise temperature distribution and even contact pressure form the basis for durable DTF transfers, clean flex film results and consistent sublimation prints. Only when heat and pressure are reliably controlled can prints remain durable, colour-stable and wash-resistant. In our range, we rely on Secabo brand Heat Presses. These stand for precise control of temperature and time, optimum results and practice-orientated functions. Depending on the model, they offer modular designs and the option of app connection, making work processes more efficient and controllable.

The right Heat Press for your workflow

- If you regularly process large quantities, pneumatic Heat Presses or double plate presses are indispensable. Models such as the Secabo TPD7 significantly reduce unproductive downtimes, as you can prepare the next textile while the press is still working. This ensures a smooth workflow, consistent results and a noticeable increase in productivity in everyday textile finishing.

- Safety & convenience: Auto-Open Heat Presses open automatically after the set time has elapsed. This reduces the risk of overheating or burning textiles and ensures consistent results. At the same time, you can focus on other work steps such as weeding during the pressing process and organise your workflow more efficiently.

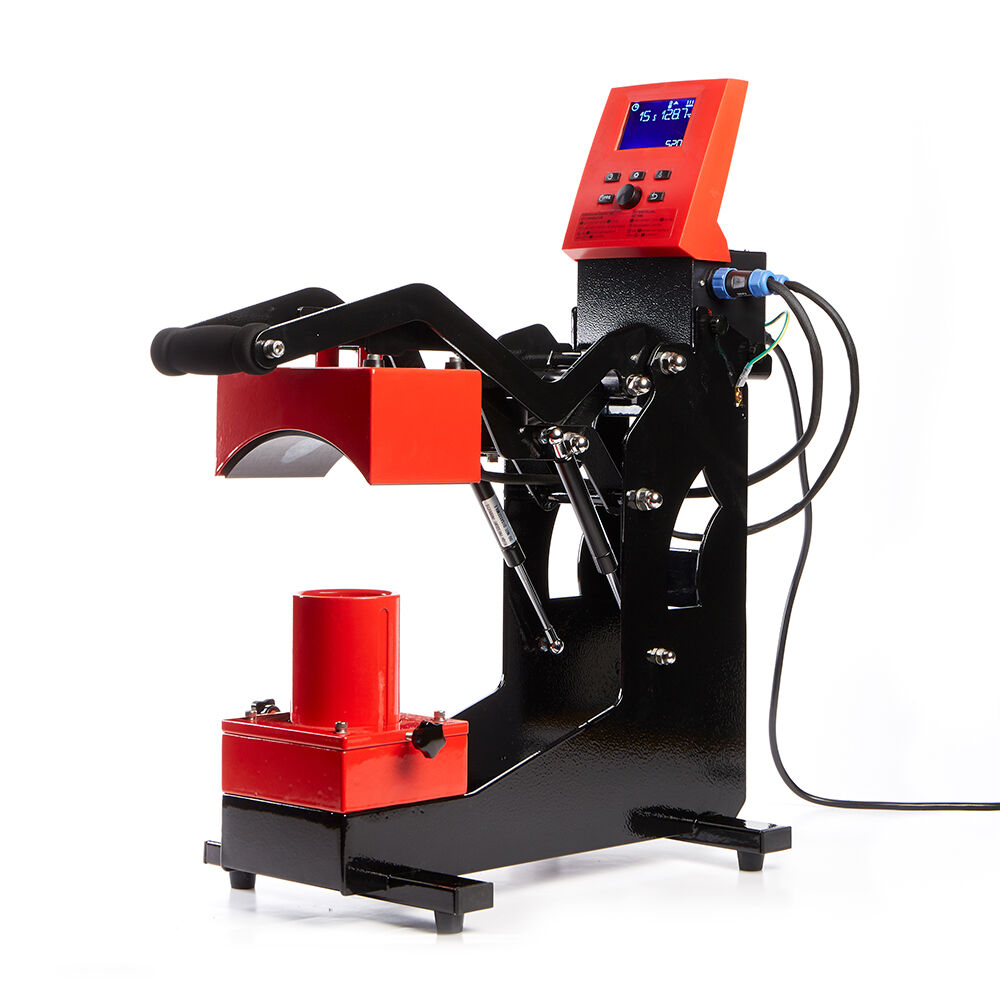

- Versatility: Specialised Heat Presses such as Mug Presses, Cap Presses and Ball Presses are ideal for promotional product retailers. These solutions allow you to expand your range in a targeted manner and go far beyond classic T-shirt printing. This allows you to efficiently finish different products and flexibly adapt your portfolio to customer requirements.