From print to finished transfer: high-performance components for professionals

In the modern DTF workflow, speed after printing determines profitability. If you work manually with scissors or a slitter rewinder, you lose valuable time. Our "DTF Workflow & Finishing" category offers you the tools to industrialise this process.

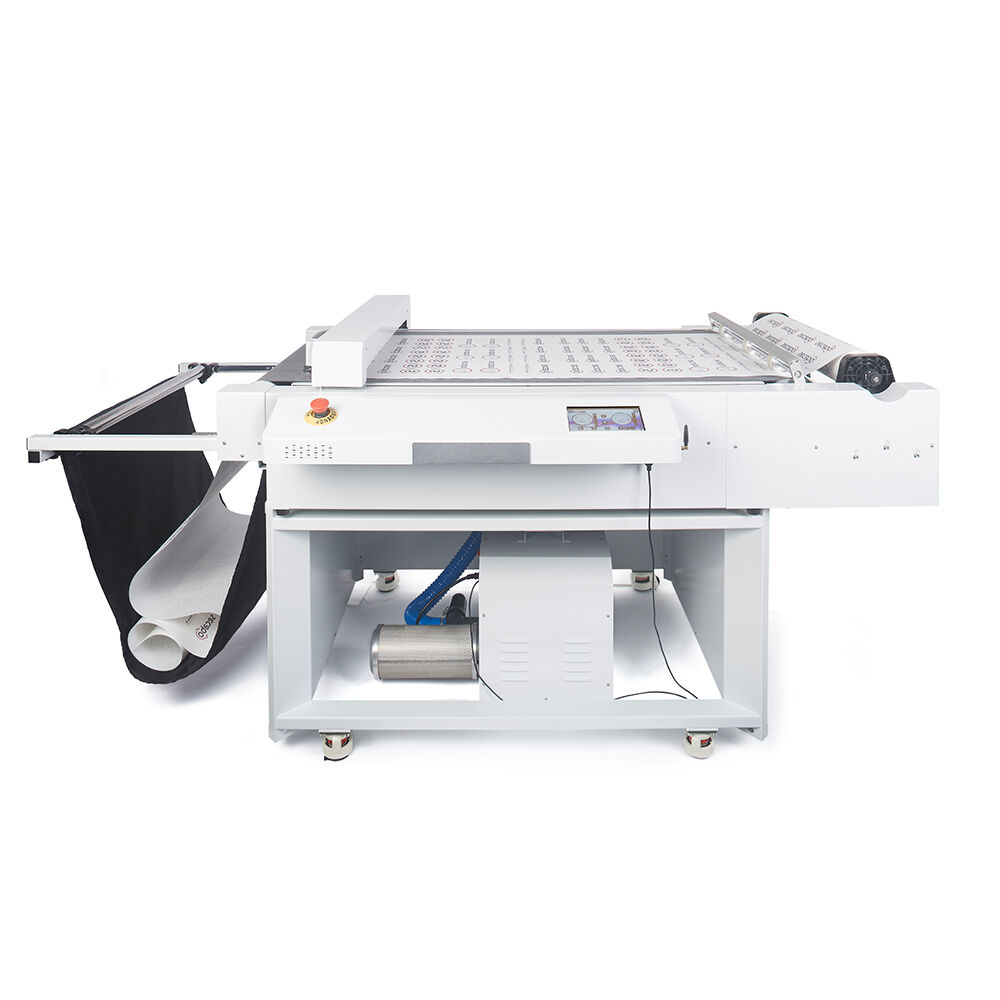

Secabo MultiCut Pro: The revolution for roll goods

The MultiCut Pro is much more than a conventional flatbed plotter. Equipped with an innovative conveyor belt system, it automatically feeds DTF roll goods and cuts them precisely. It combines the stability of a flatbed cutter with the endless productivity of a roller system - the perfect solution for DTF forges and professional finishers.

Precise cutting with MultiTrim

For customers who rely on large quantities of identical sheets or sheets, our new systems offer the necessary performance:

- MultiTrim: the specialist for fast, automated longitudinal and cross-cutting. It makes the manual separation of printed sheets superfluous.

The 2 tool wonder BladeX2

With the BladeX2, you can perform customised kiss-cutting and full-cutting in one machine. This enables the cutting of DTF, UV DTF

Why invest in automation?

Every minute your employees spend manually sorting and cutting is unproductive time. Our finishing hardware quickly pays for itself through:

- Higher throughput: process more jobs in the same amount of time.

- Lower error rate: No wasted motifs due to manual feeding.

- Consistent quality: Clean edges and precise contours that impress your customers.

Optimise your DTF process now and rely on the technological superiority of Secabo.