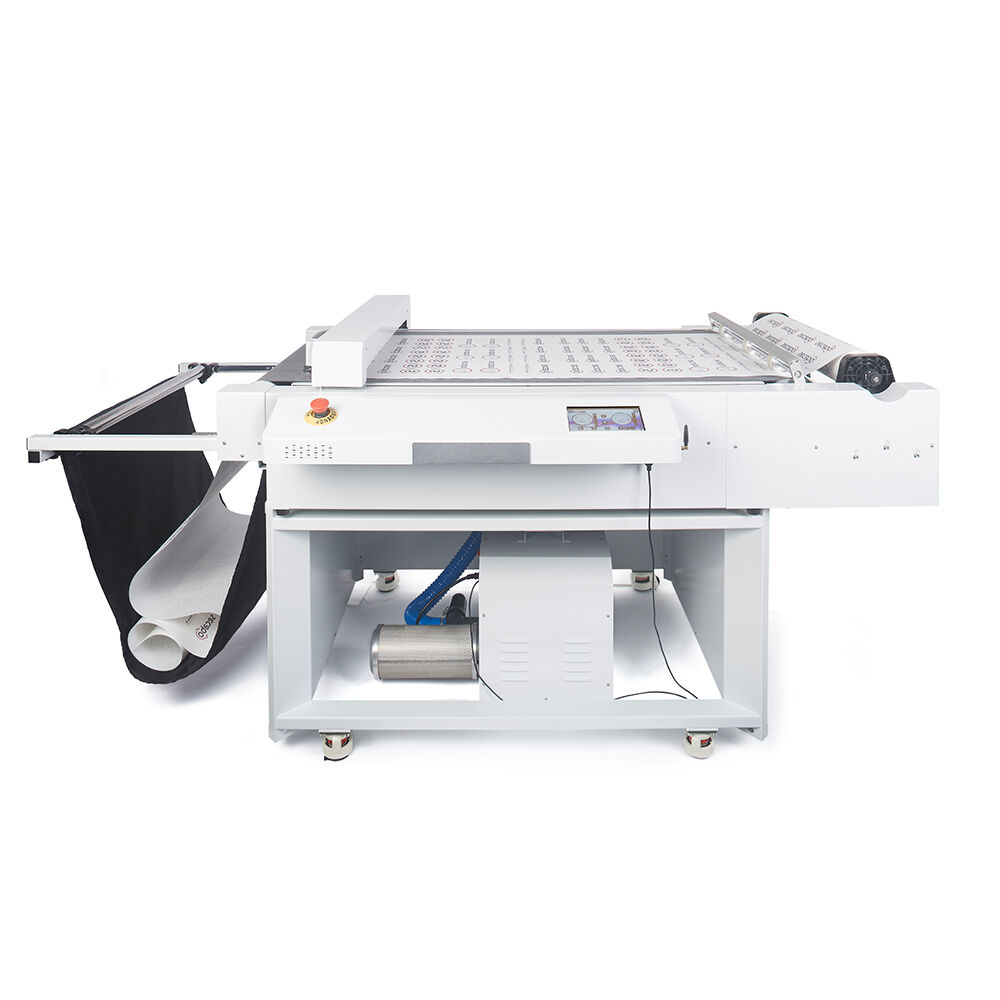

Maximum control and versatility with flatbed technology

In contrast to classic roll plotters, the material on a flatbed cutter (flatbed plotter) is firmly fixed to the work surface. This eliminates the risk of material slippage or distortion and enables results that set standards in signmaking and industrial labelling.

Advantages of the Secabo FC series

The flatbed cutters from Secabo have been specially developed for users who require flexibility for short and medium runs.

- Vacuum table & fixation: Thanks to the integrated suction pump or electrostatic adhesion, even light materials such as paper or thin films remain perfectly in position during the cutting process.

- Versatile tools: In addition to classic cutting, many models also enable creasing and perforating, making them the perfect tool for packaging prototyping.

- Precise contour cutting: In combination with the LAPOS Q camera system, register marks on sheet material (such as DTF transfers or offset prints) are recognised at lightning speed and cut out precisely.

Areas of application: From DTF to prototyping

Flatbed cutters close the gap between manual cutting and large-scale industrial production. They are indispensable for:

- DTF finishing: precise cutting of printed transfer sheets without cutting mark offset.

- Stickers & labels: Production of "kiss-cut" or "die-cut" stickers on sheets.

- Packaging design: creasing and cutting of cardboard packaging for samples and small batches.

Invest in a technology that professionalises your workflow and delivers reliable results even with challenging materials such as magnetic foils or thick paper.