DTF optimisation & process reliability - why pneumatic presses are indispensable

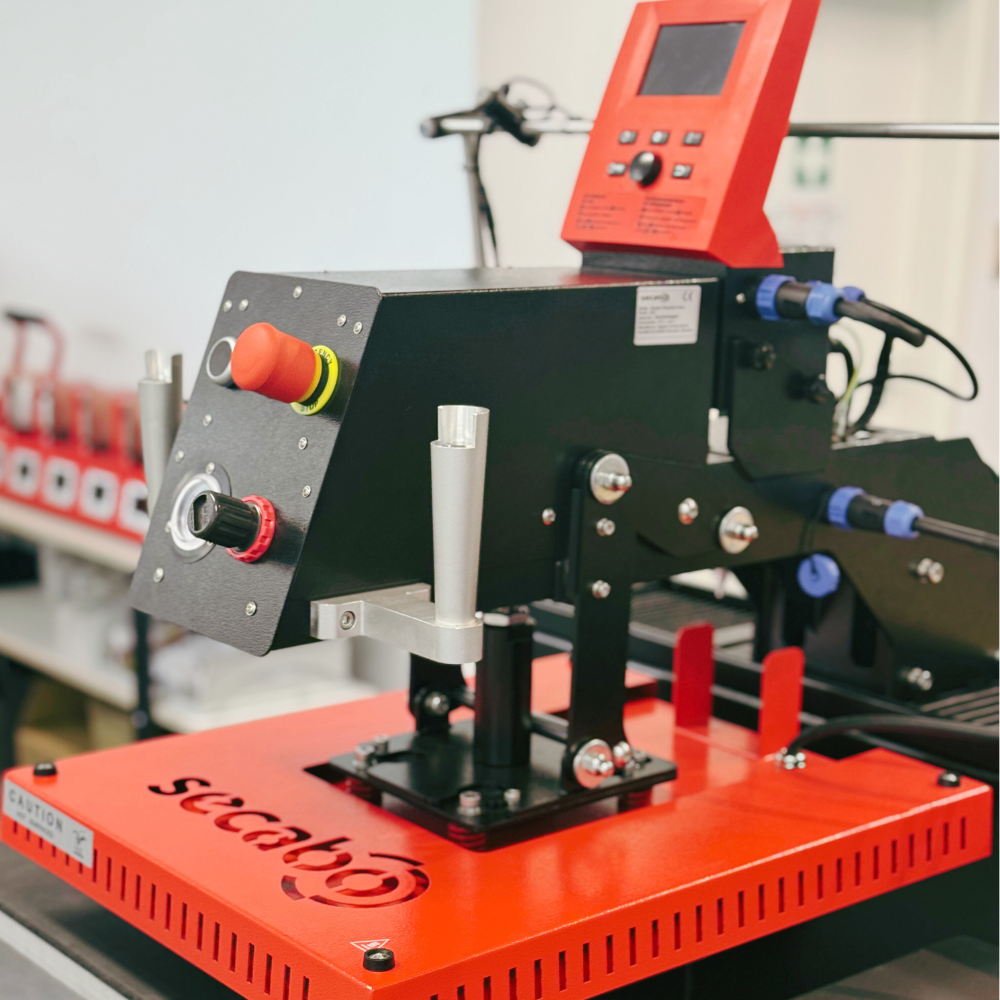

In modern textile finishing, especially in the DTF (direct-to-film) sector, the contact pressure is the critical factor for the durability of the transfer, alongside time and temperature. Pneumatic presses relieve the operator of physical labour and guarantee that every pressing process is carried out with exactly the same pressure.

The advantages of the pneumatic drive at a glance:

- Constant reproducibility: While manual presses can vary depending on the amount of force applied by the operator, the pneumatic system (controlled by a compressor) always delivers identical pressure. This is essential for certification and quality assurance for large orders.

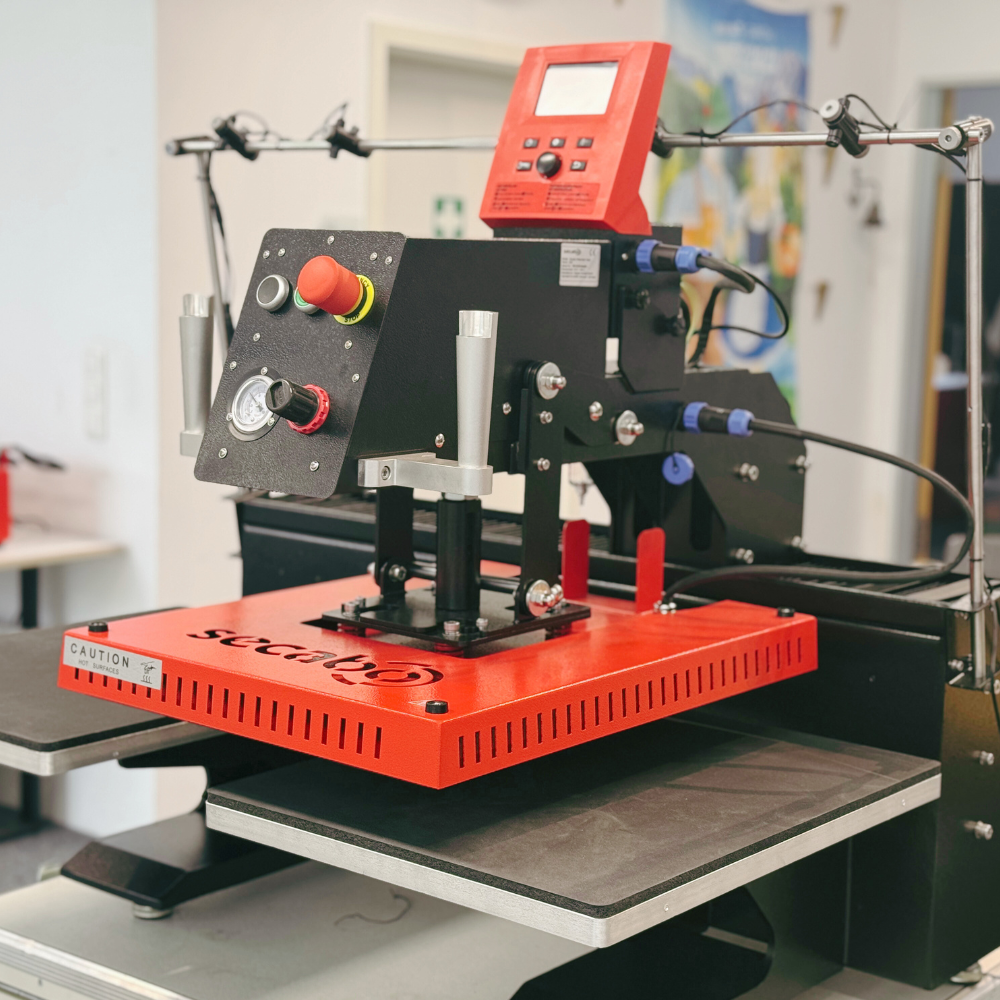

- Fatigue-free working: The pressing process is conveniently triggered at the touch of a button or foot switch. This is easy on your employees' joints and keeps productivity high even at the end of a shift.

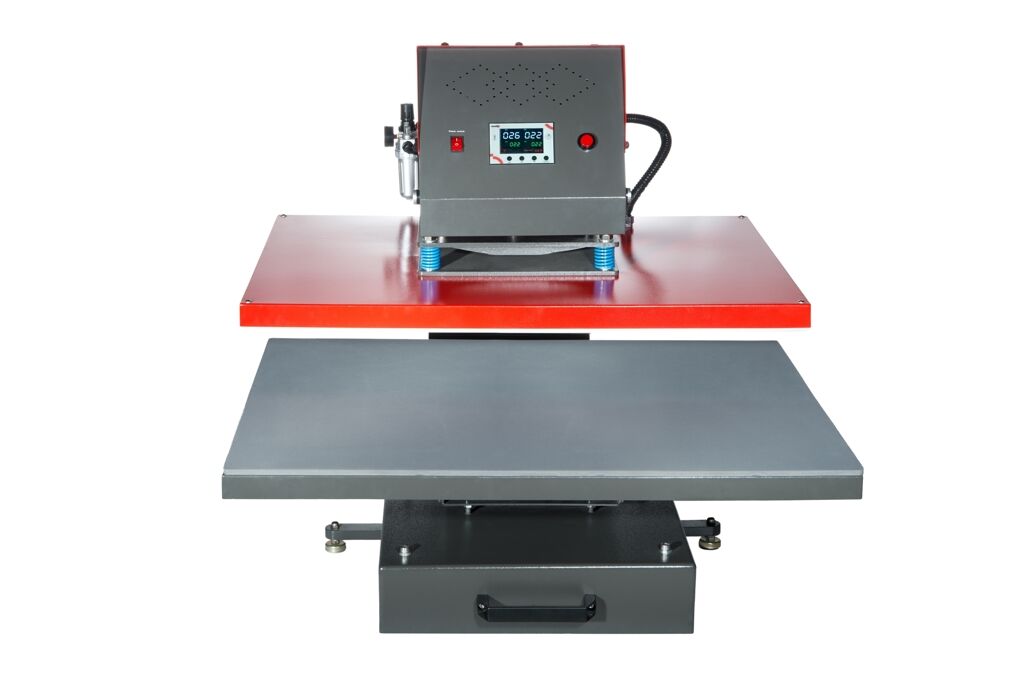

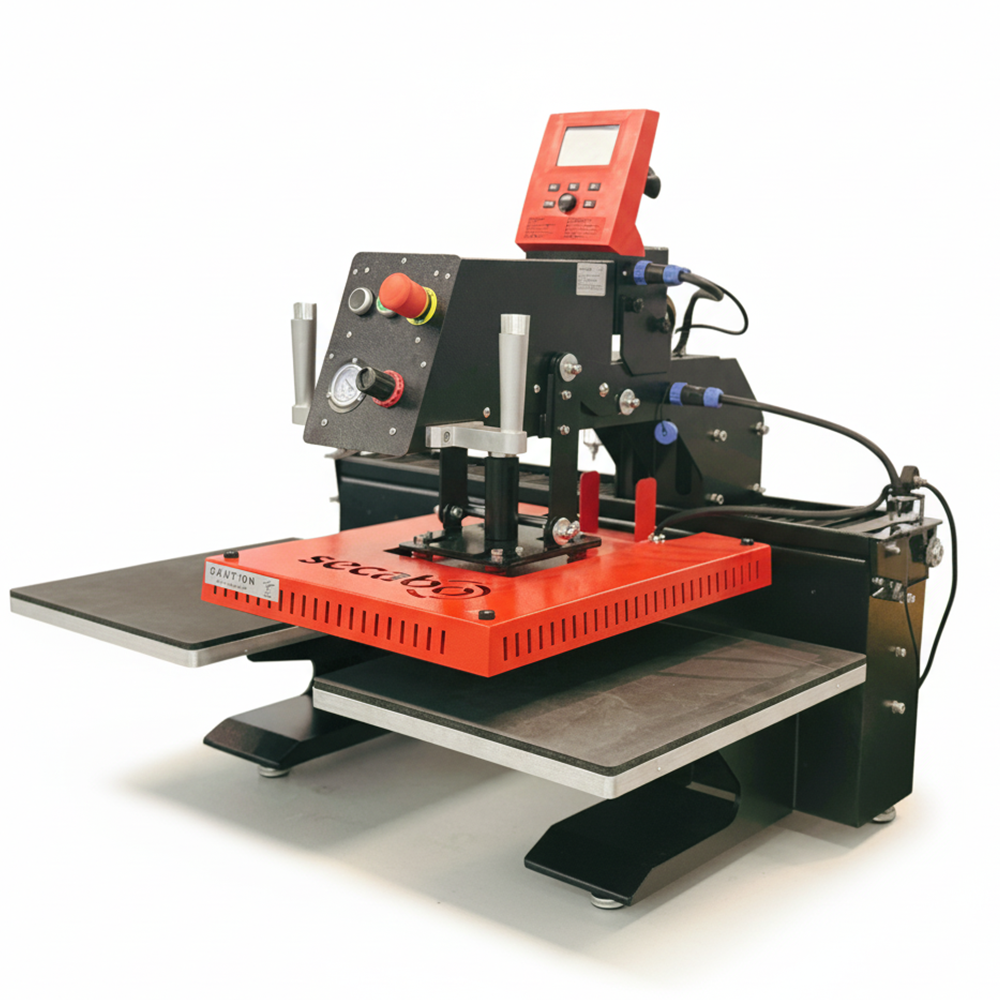

- Perfect for the DTF workflow: In combination with the Secabo DTF Multicut Pro, pneumatic double plate presses such as the TPD7 form a highly efficient production line. While one plate is pressing, you are already preparing the next textile on the second plate - eliminating unproductive waiting times.

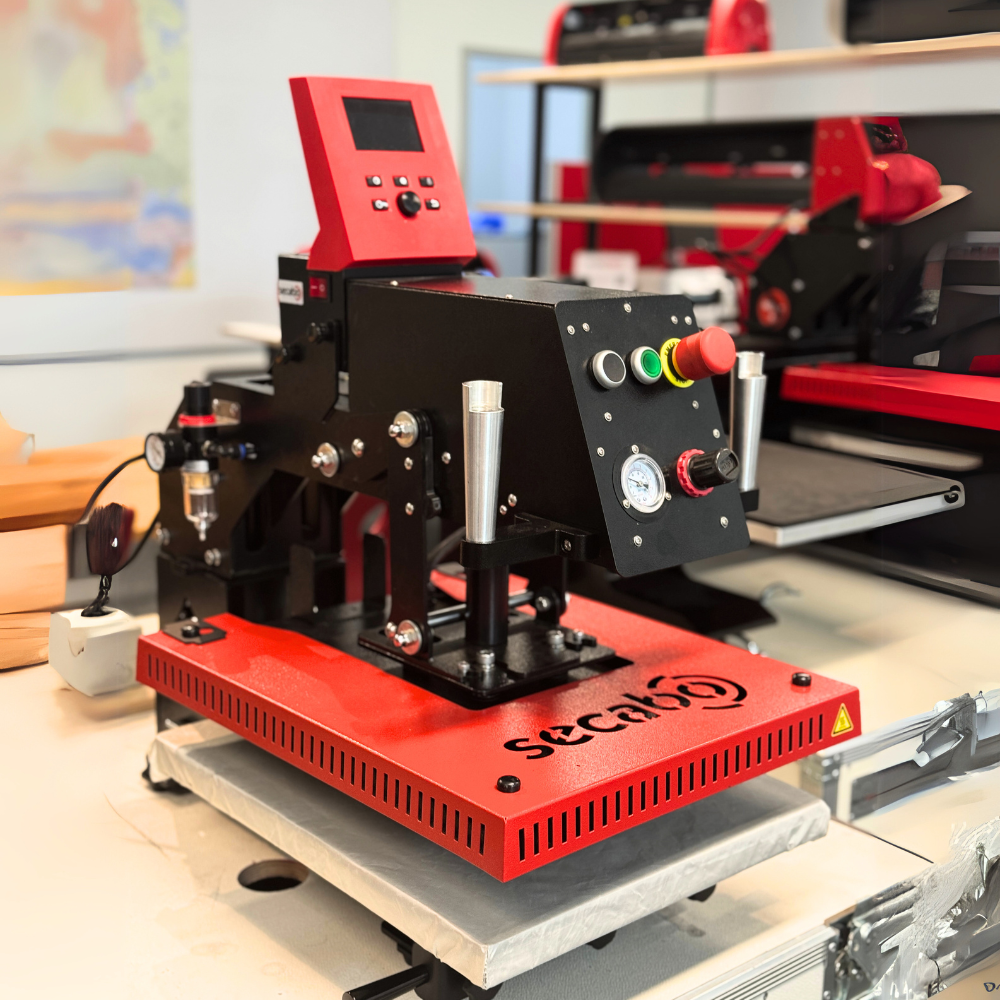

Innovation from Secabo: Smart & modular

Our pneumatic models are much more than simple hot presses. Thanks to integration into the Secabo Smart network, parameters can be precisely controlled and monitored. The membrane base plates also make it possible to compensate for unevenness such as seams, buttons or zips using air cushions. This allows you to achieve a first-class transfer result without print marks, even on difficult textiles.