Productivity redefined - why a double plate press speeds up your business

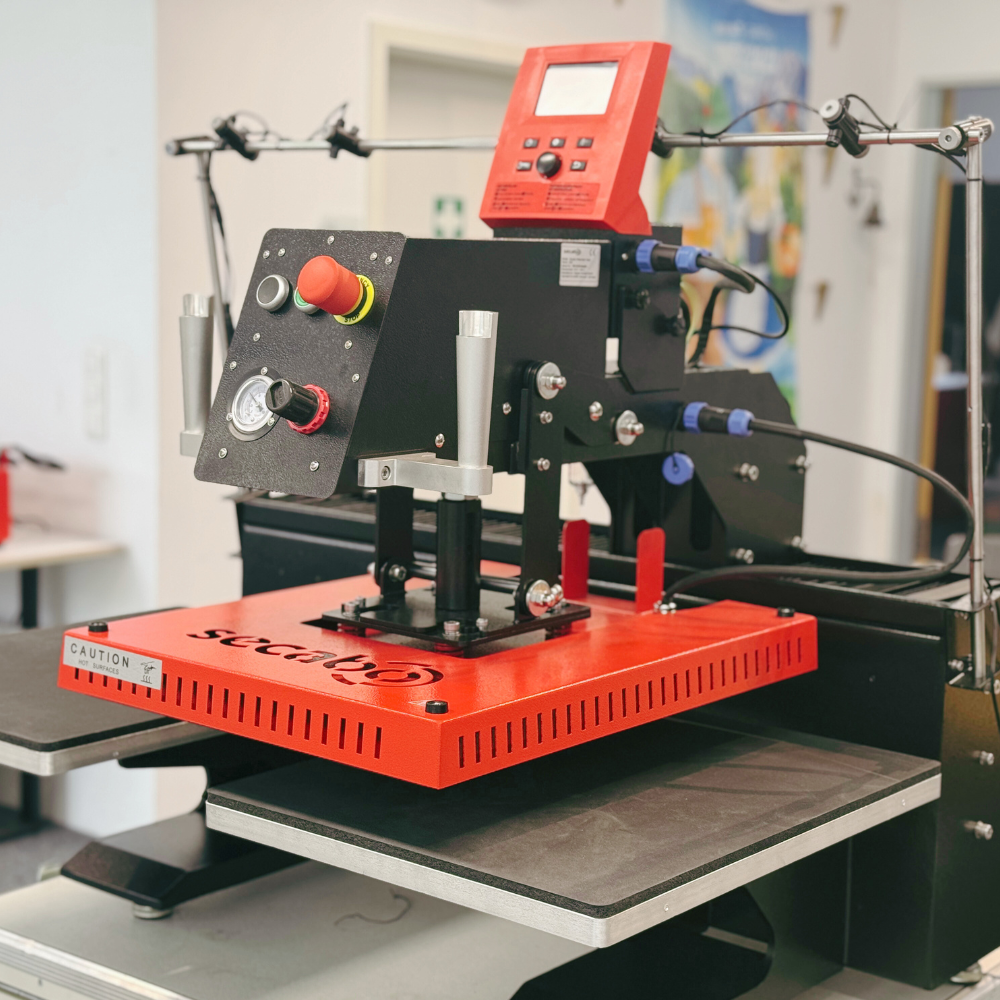

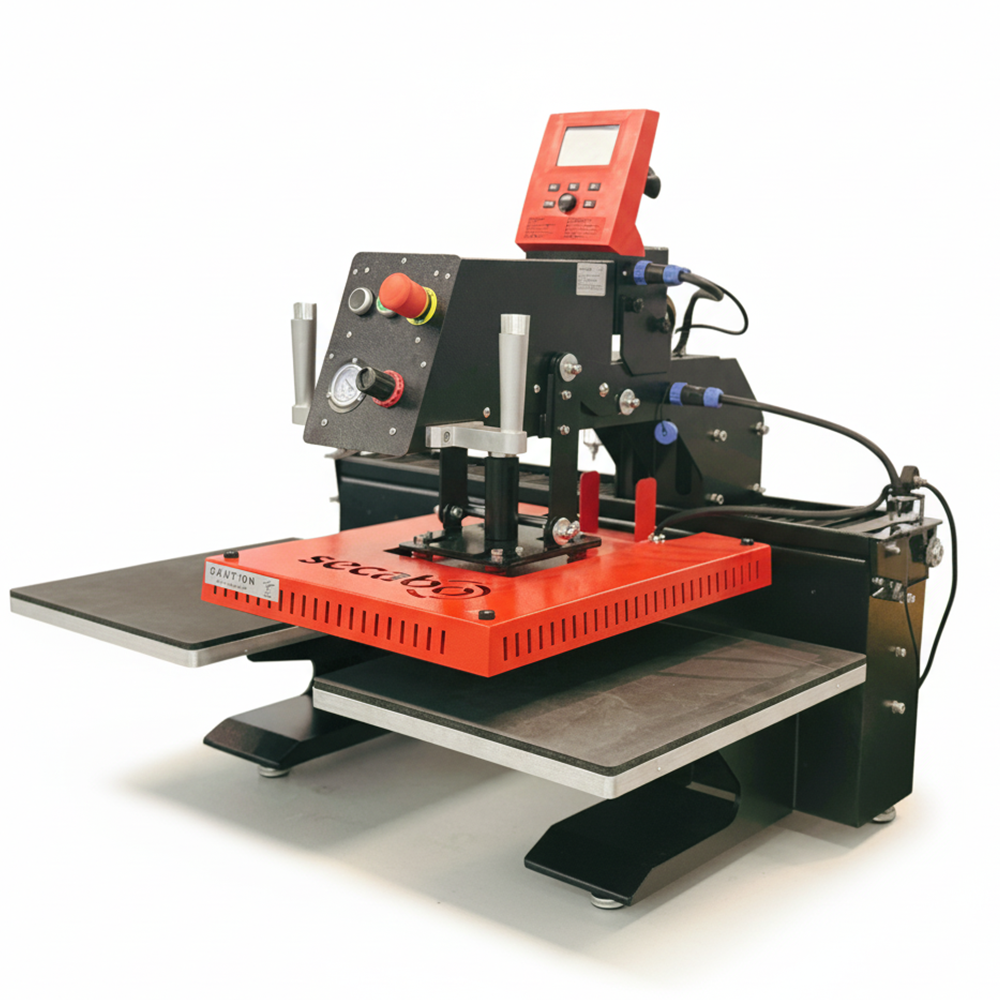

Time is a decisive factor in professional textile printing. A double plate press significantly reduces unproductive waiting times during the pressing process. While one plate is pressing, the next textile can already be prepared on the second. This almost continuous workflow is a clear competitive advantage, especially for DTF (direct-to-film) transfers and large series of flex and flock film transfers.

The advantages of our double plate solutions:

- Simultaneous working: Two working plates maximise the utilisation of the heating plate. The result: Almost twice as many finished textiles per hour compared to single-plate models.

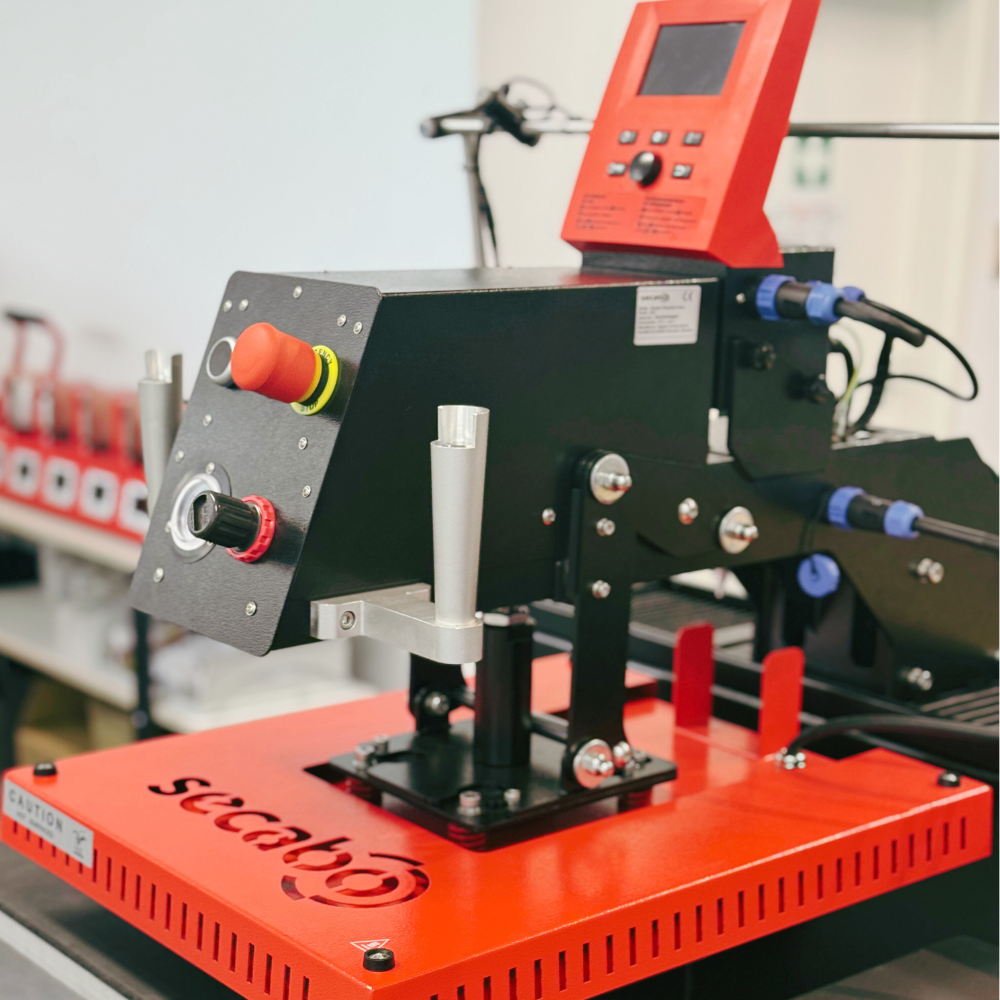

- Precision & ergonomics: Models such as the Secabo TPD7 offer pneumatic support. For you, this means: Constant contact pressure at the touch of a button, without physical effort - for reproducible results at the highest level.

- Modularity & flexibility: Many of our double plate presses can be equipped with the Secabo quick-change system. Combine different plate sizes or use membrane base plates to easily compensate for unevenness such as buttons or zips.

Optimised for the modern workflow

In combination with automated cutting solutions such as the Secabo DTF Multicut Pro, our double plate presses form the centrepiece of a highly productive production chain. Invest not just in a machine, but in an optimised process that reduces your unit costs and increases your delivery capacity.