Focus on ergonomics - why professionals rely on swivel presses

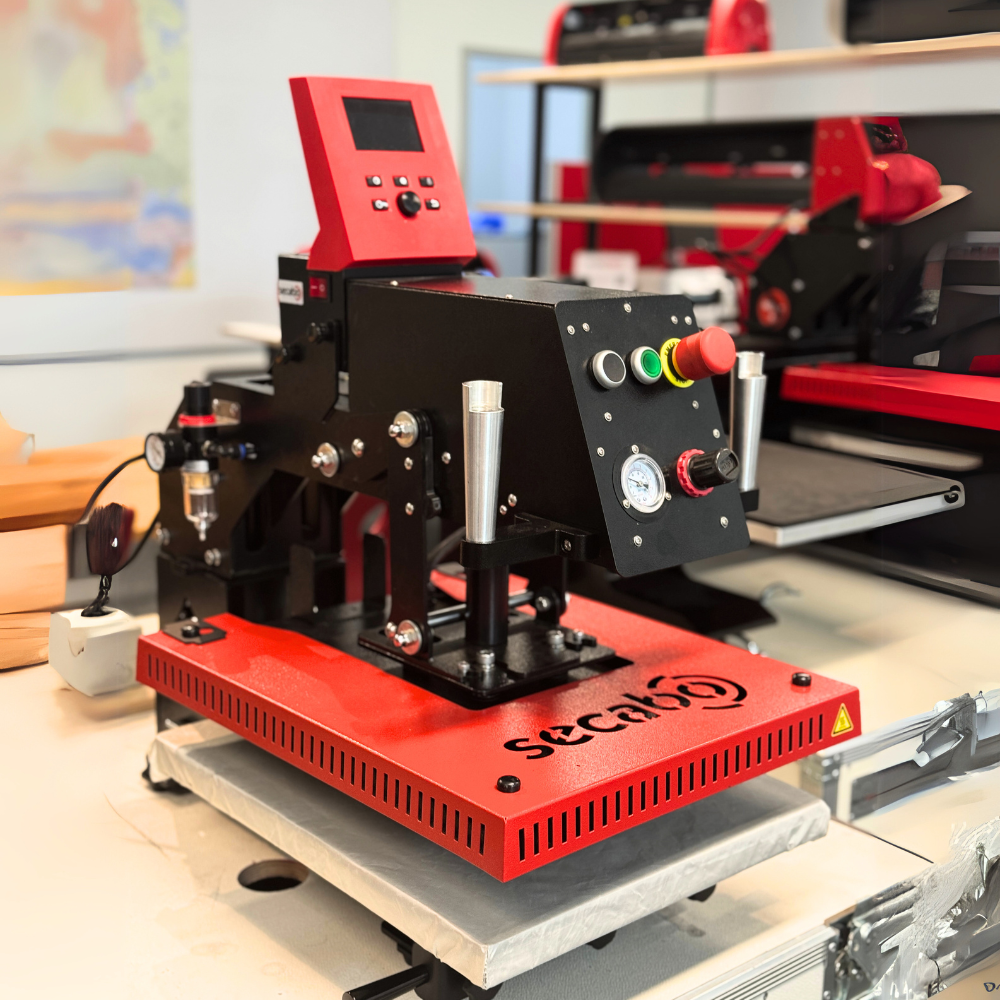

In textile finishing, the swivelling press is the preferred tool for anyone processing complex designs or thick materials. In contrast to the Clam Press, the heating plate is moved horizontally to the side. This not only creates a safer working environment away from the hot plate, but also guarantees an absolutely vertical contact pressure on the textile.

The advantages of our swivelling solutions at a glance:

- Clear view & access: As the heating plate swivels to the side, you have a clear view of the entire textile. This makes aligning logos, numbers or large DTF prints child's play.

- Vertical contact pressure: Thanks to the mechanism, the heating plate hits the textile absolutely evenly from above. This prevents transfers from slipping and ensures perfect results on thick items such as hoodies or jackets.

- Smart Secabo technology: Our swing presses, such as the Secabo TS7 Smart, are equipped with the latest control system. The Bluetooth connection to the Secabo app provides you with predefined parameters for time and temperature directly on the controller - for error-free workflows.

Efficiency meets convenience

Swivel presses are ideal for users who value convenience and durability. The robust design of the Secabo hardware ensures constant heat distribution across the entire surface, which is particularly essential for sublimation printing or large-format transfers. Combine your swing press with a quick-change system to increase your productivity even further.