XXL transfer printing without compromise - the world of large-format presses

Large-format Heat Presses (XXL format Heat Presses) are the centrepiece for companies specialising in large-scale sublimation or industrial textile finishing. While conventional presses often reach their limits with large-format designs, large-format systems offer absolutely homogeneous heat distribution across the entire work surface - a critical factor in avoiding colour differences (clouding).

Areas of application and technical superiority:

- Sublimation in large format: Ideal for the production of sports jerseys, where the design is transferred to the entire surface of the fabric before sewing. Rigid media such as aluminium panels or large-format photo gifts can also be precisely finished in this way.

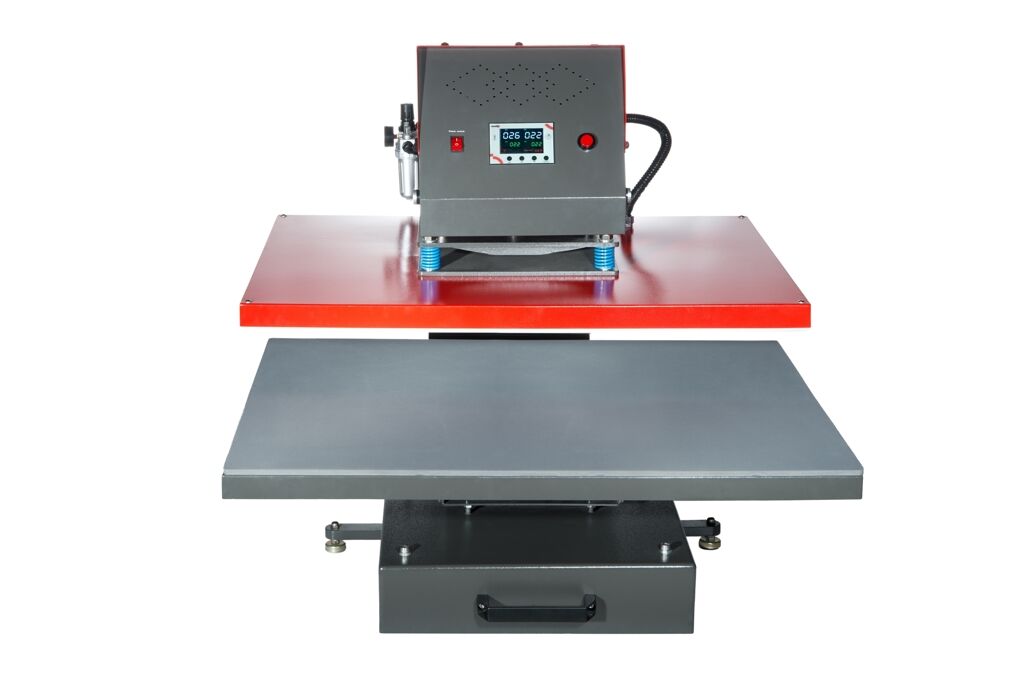

- Pneumatic support: Due to the enormous surface area of the heating plates, manual sewing is hardly possible. Our large-format presses therefore usually work pneumatically. This guarantees an extremely high and, above all, uniform contact pressure, which is essential for colouring the fibres.

- Pull-out systems: To facilitate the handling of large textiles or media, many models have practical drawer systems or even double plate configurations to massively speed up the workflow.

Quality from Secabo for the highest demands

In this size range, process reliability is everything. Secabo large format solutions are characterised by their robust design and high-precision digital controllers. The controller monitors the temperature precisely so that no deviations occur, even during long pressing processes. Invest in hardware that expands your capacities and opens up new markets in the advertising technology and fashion industry.